CHALLENGE

What goes into making a product? Understand why why the Grand Wall Phone was such a successful product.

SOLUTION

Use forensic analysis skills and knowledge of materials and manufacturing processes to tear down an existing manufactured product, analyze its components, materials and construction and apply those findings in the development of a new product.

HOW I HELPED

Design Researcher

Tear Down/Disassembly

Concept Development

Grand Wall Phone

PROCESS

Can we disassemble a product to learn more about it?

The grand wall phone was used for communication and connection. It was made of good quality materials that withstood a busy kitchen environment.

70 years after its original introduction and in a society that has long surpassed the need for a wall phone, the grand wall phone is still a statement product due to its organic shapes and bulbous form giving the viewer joy.

Bell Telephone Magazine Ad

Bell Telephone Magazine Ad

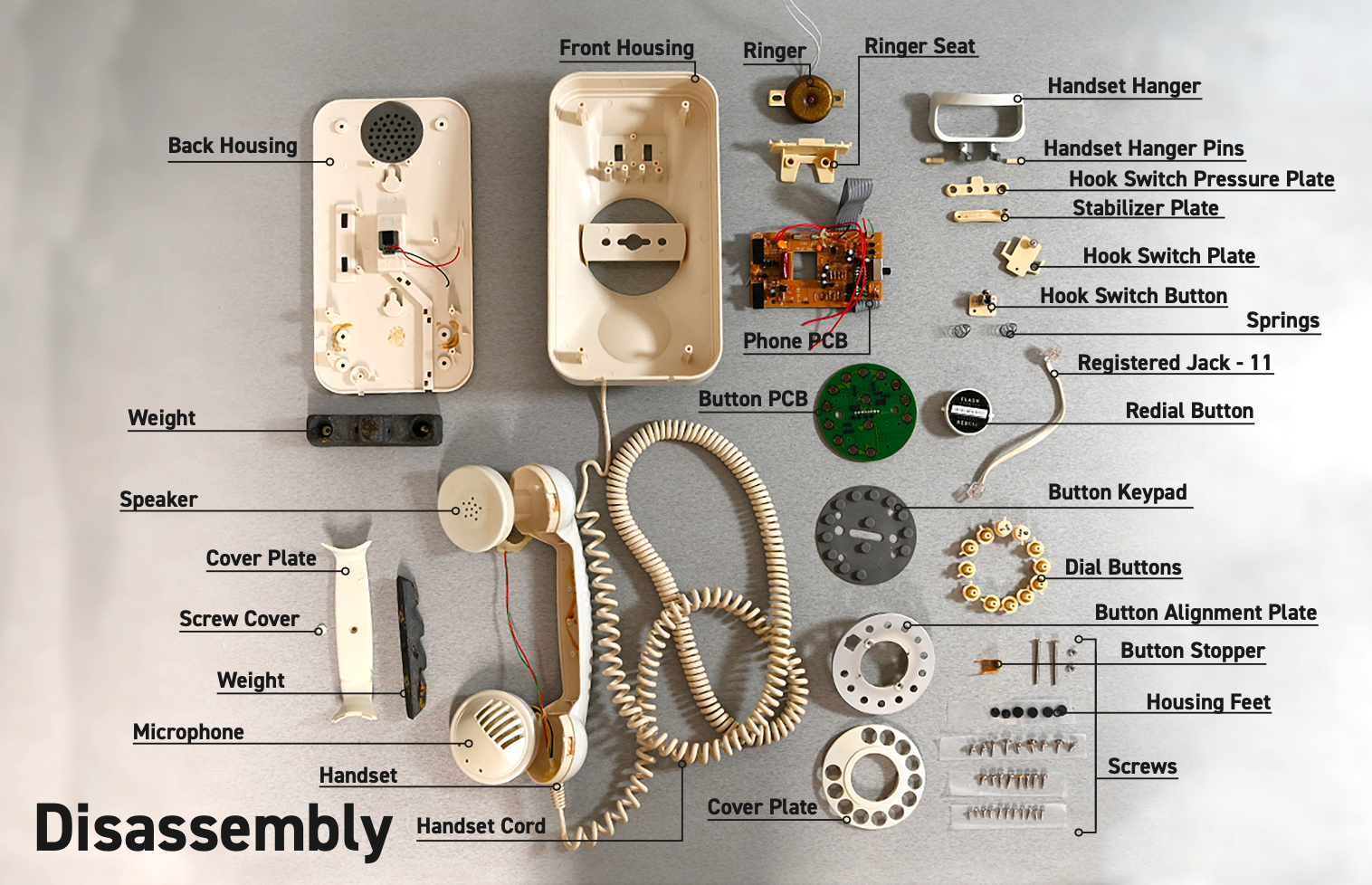

Phone Disassembly

Phone Disassembly Label Parts

The entire grand wall phone is made with high quality and durable material. There are numerous parts that go into making this project function well.

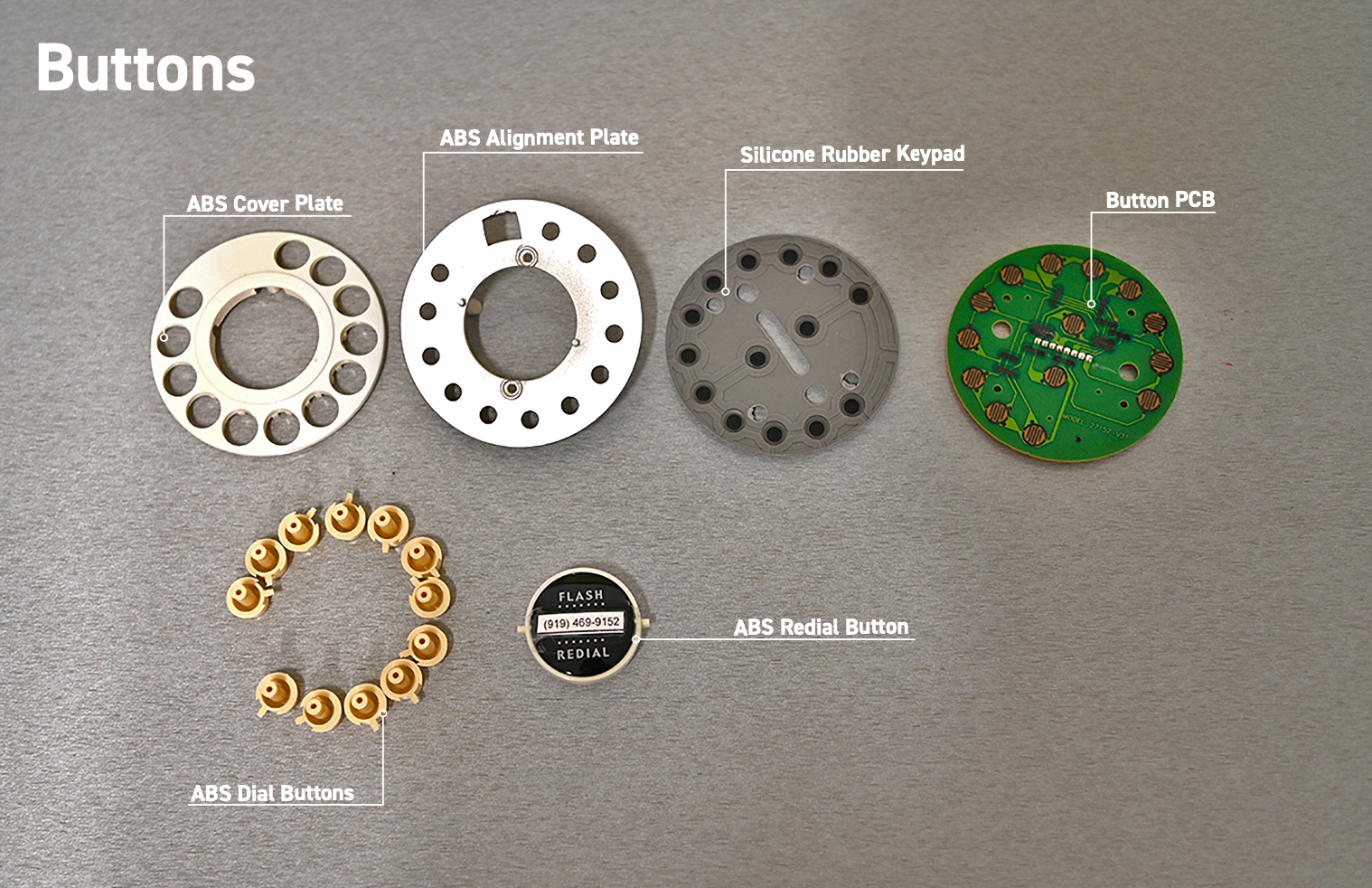

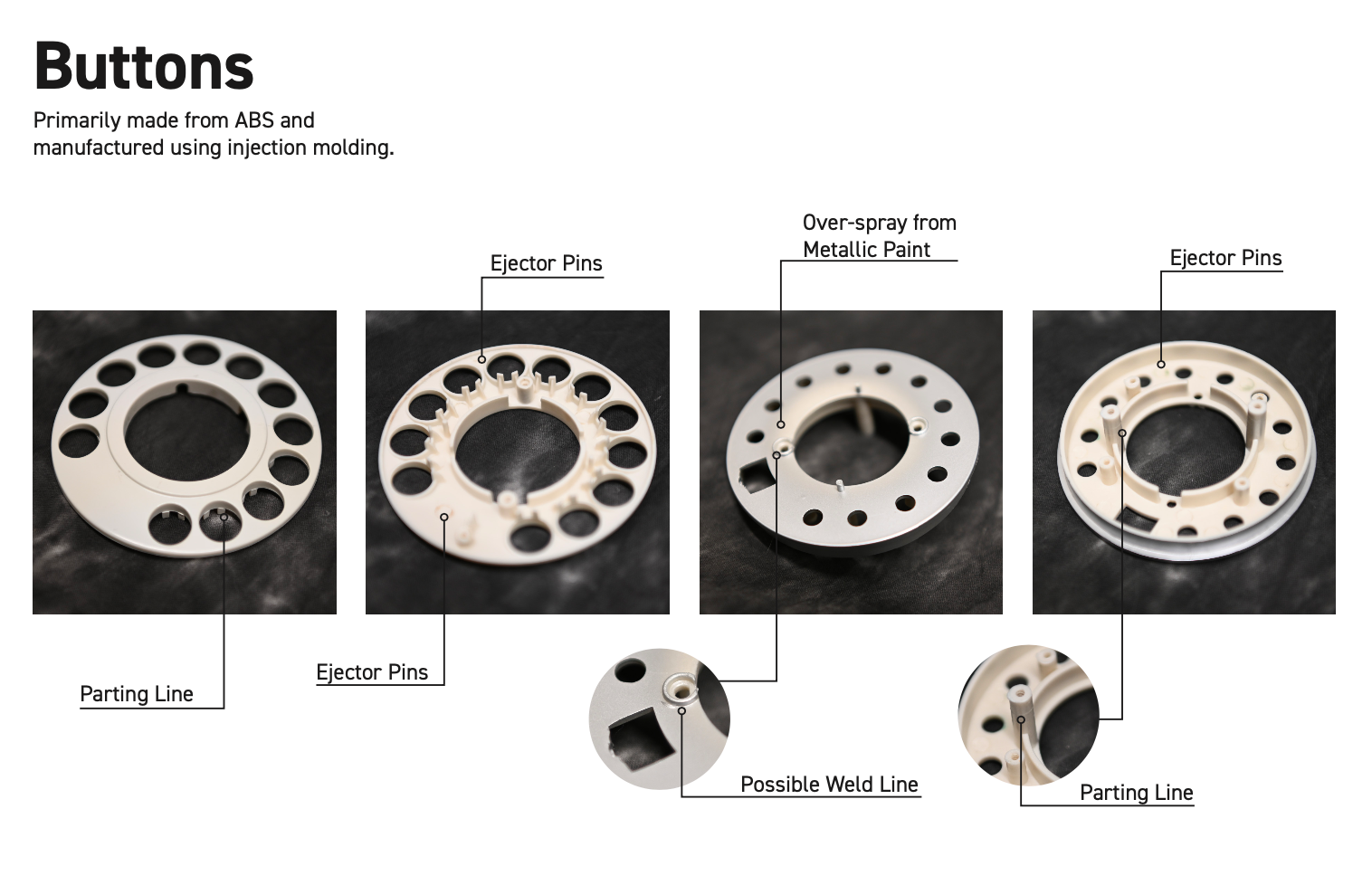

BUTTONS

The buttons of the grand wall phone are primarily made from ABS and manufactured using injection molding. The rubber keypad is made using silicone while the PCB has multiple materials and layers.

Button Components

Individual button components

Individual button components

Individual button components

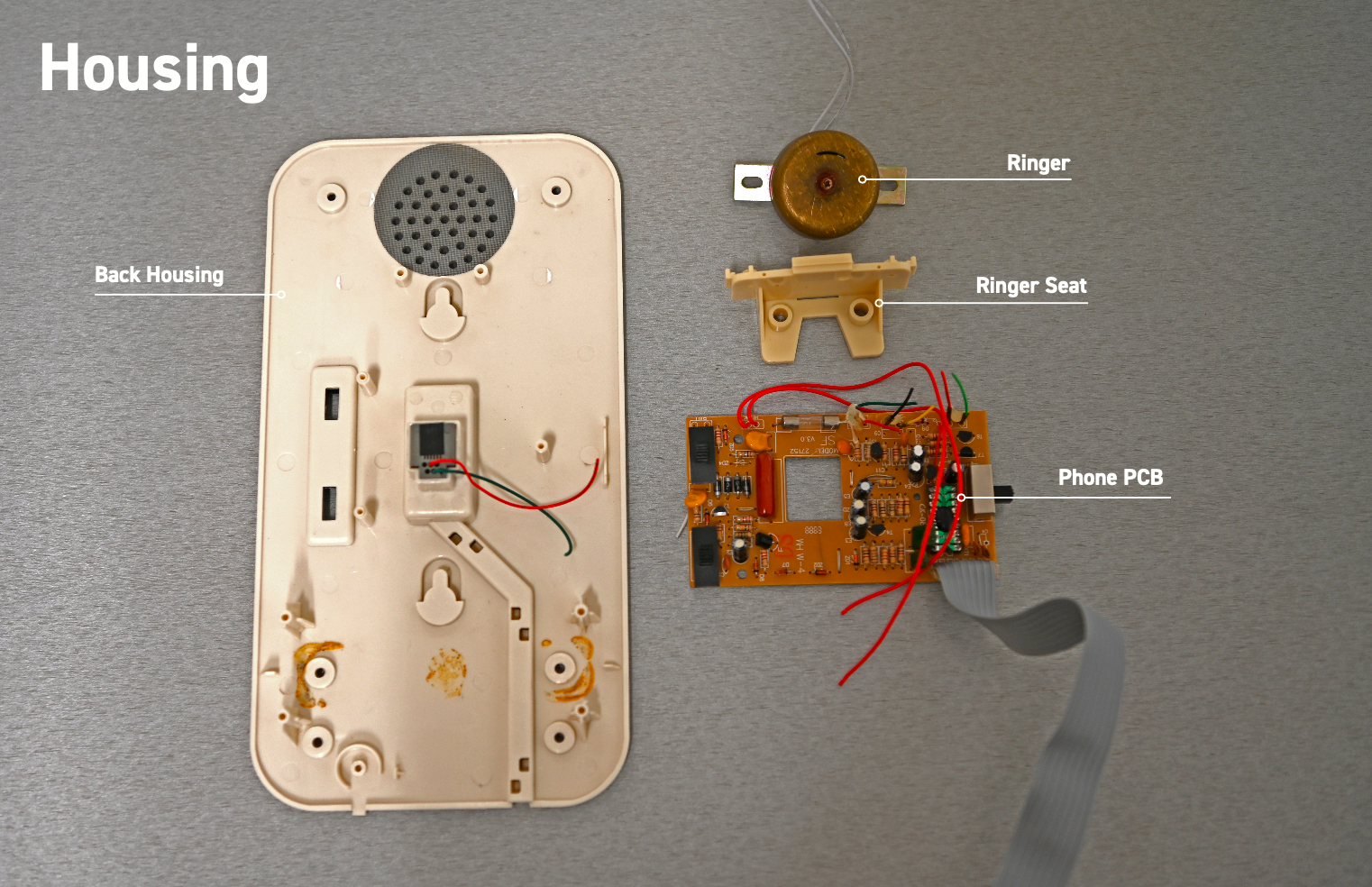

Back housing and some internal parts

Front Housing Outside

Front Housing Inside

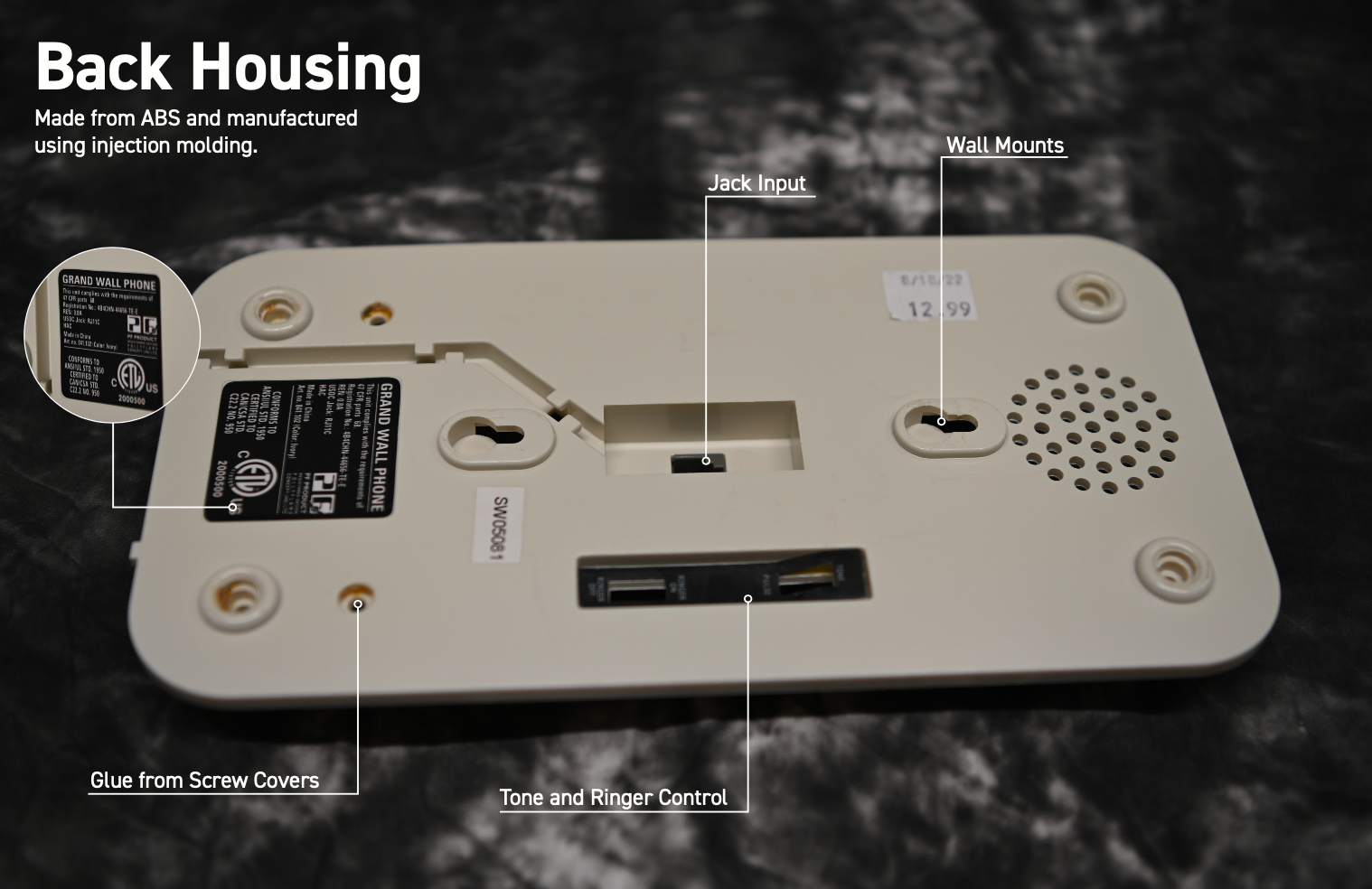

Back Housing Outside

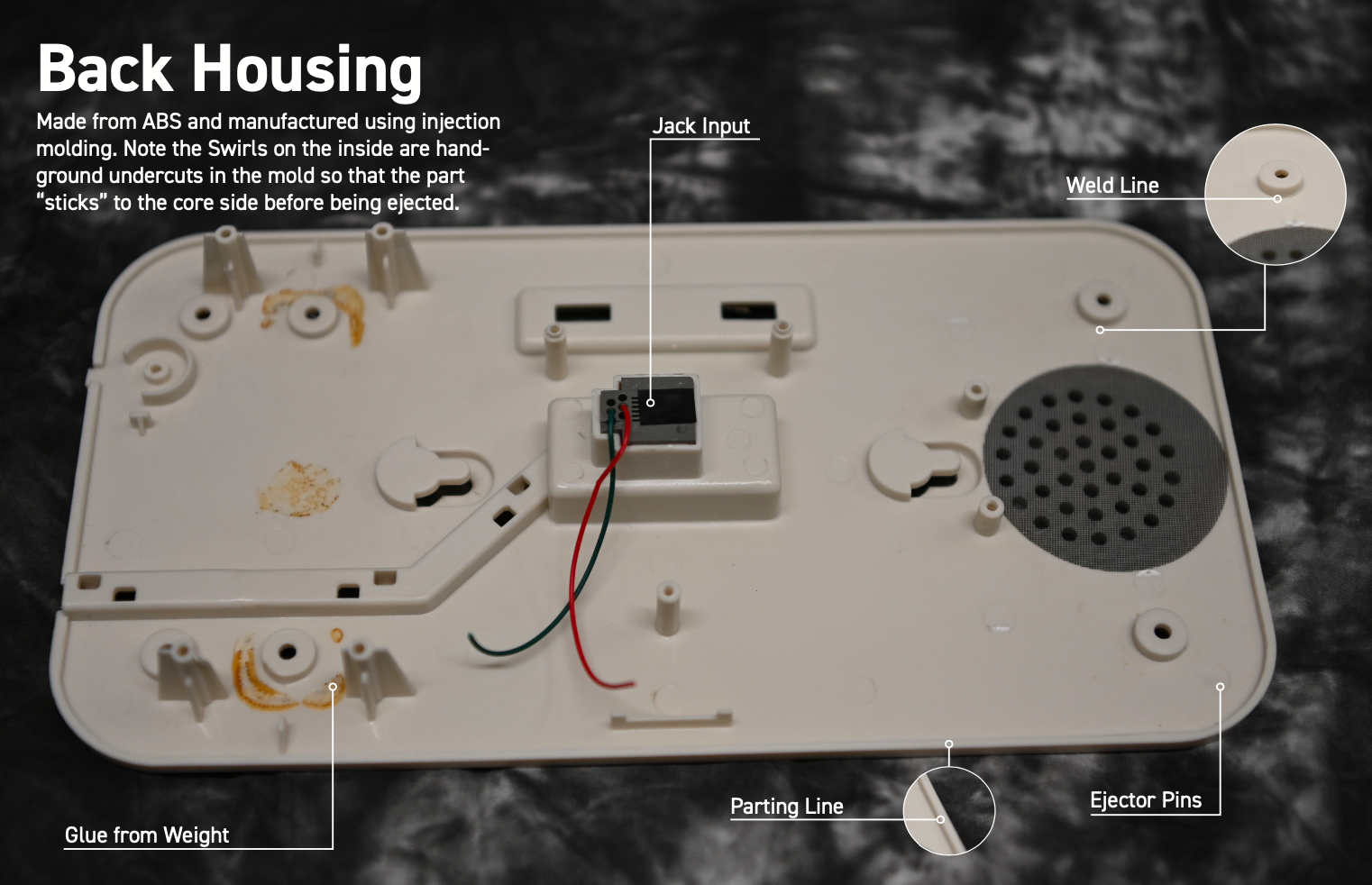

Back Housing Inside

HOUSING

The housing is also made from ABS plastic and made using injection molding. This is made evident from parting lines and ejector pins. Also, there are swirls on the inside the the plastic, an impression from the mold used to make the housing.

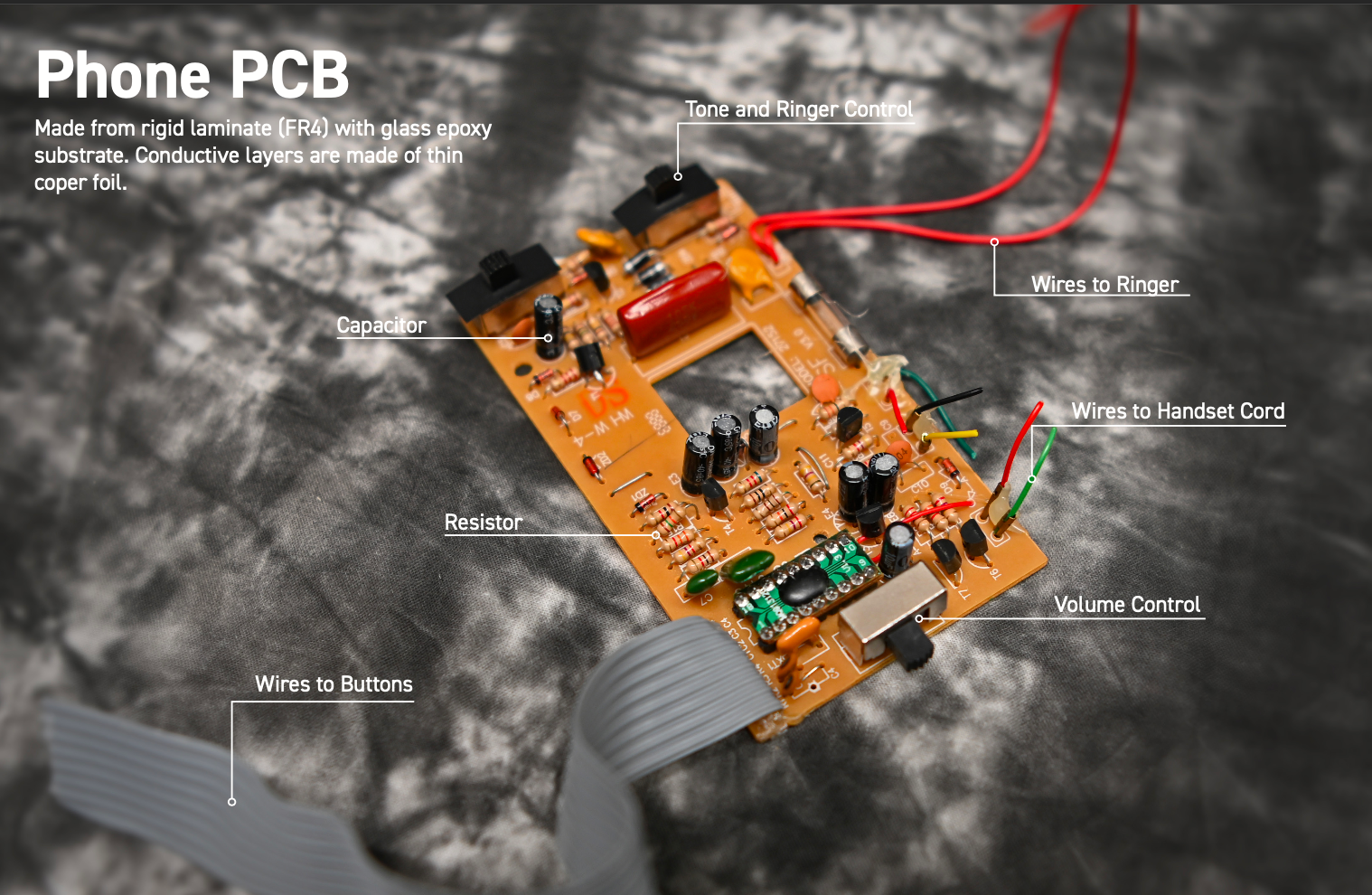

INTERNAL COMPONENTS

Some internal comments include the PCB and the ringer assembly. The PCB is made from rigid laminate with a glossy epoxy substrate. Conductive layers are made of thin copper foil.

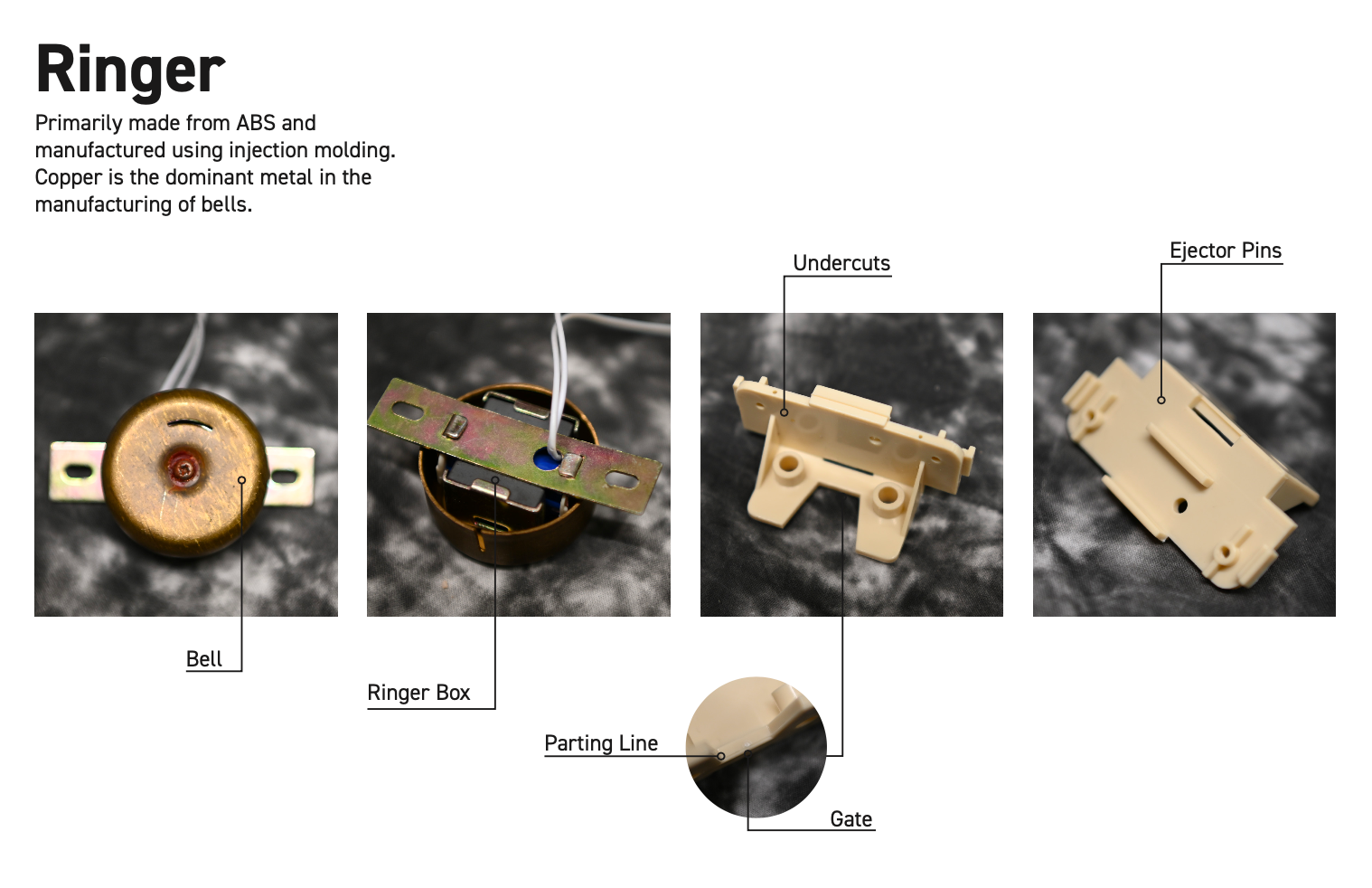

The ringer housing is also made from ABS. Copper is the dominant metal in the manufacturing of bells.

Phone PCB

Phone Ringer

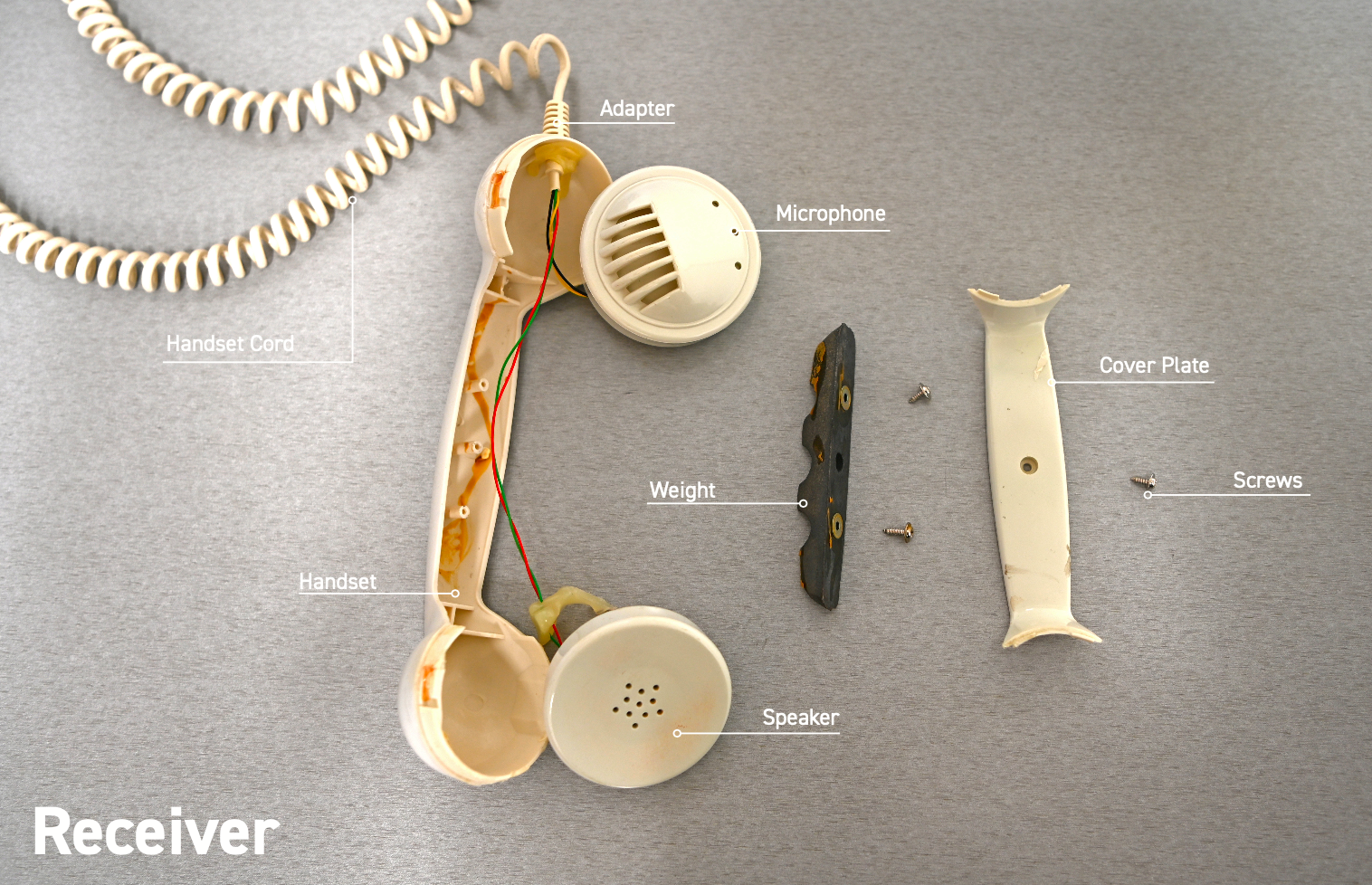

Phone Handset

Phone Receiver

Phone Handle

Phone Speaker and Microphone

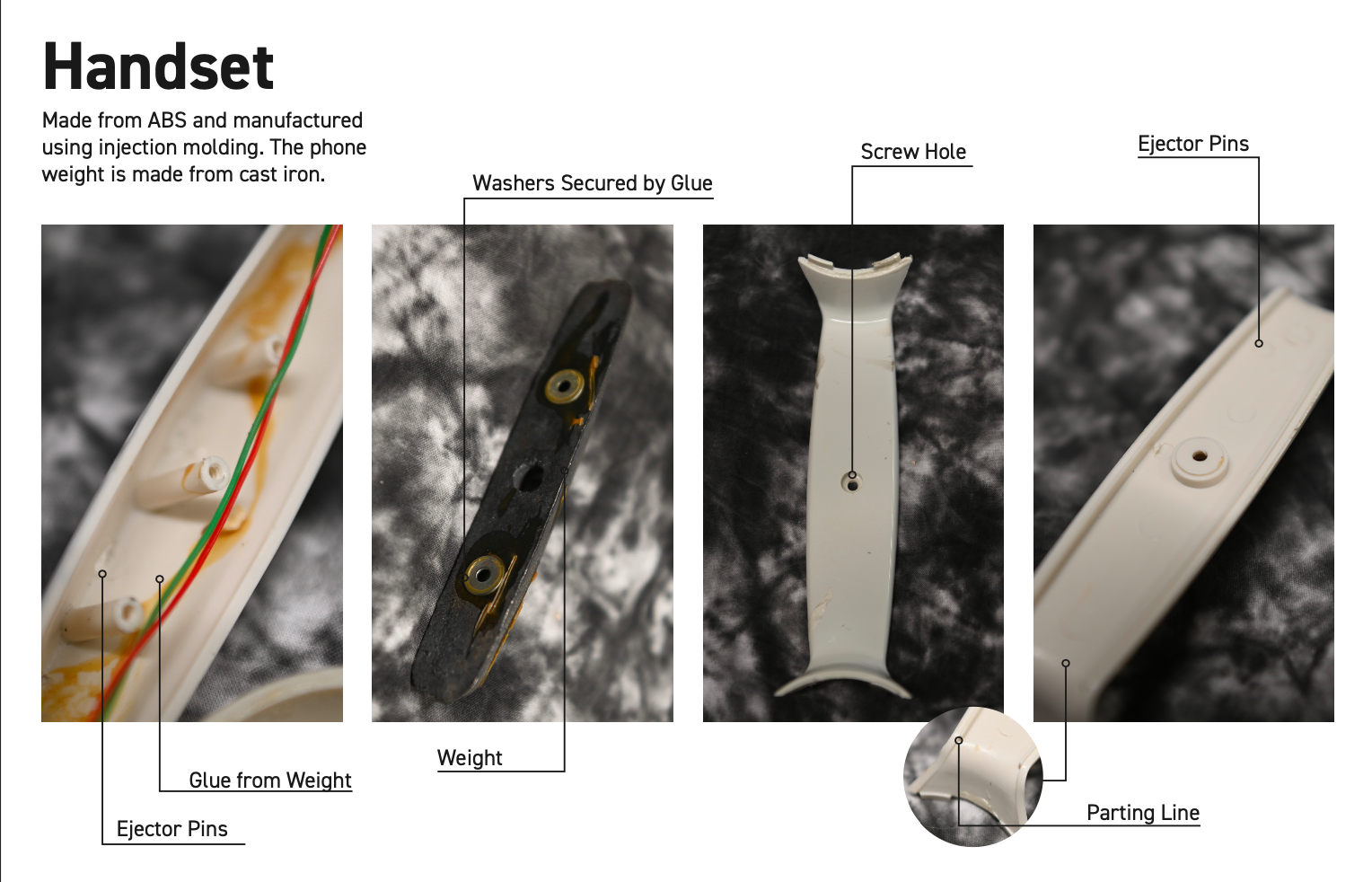

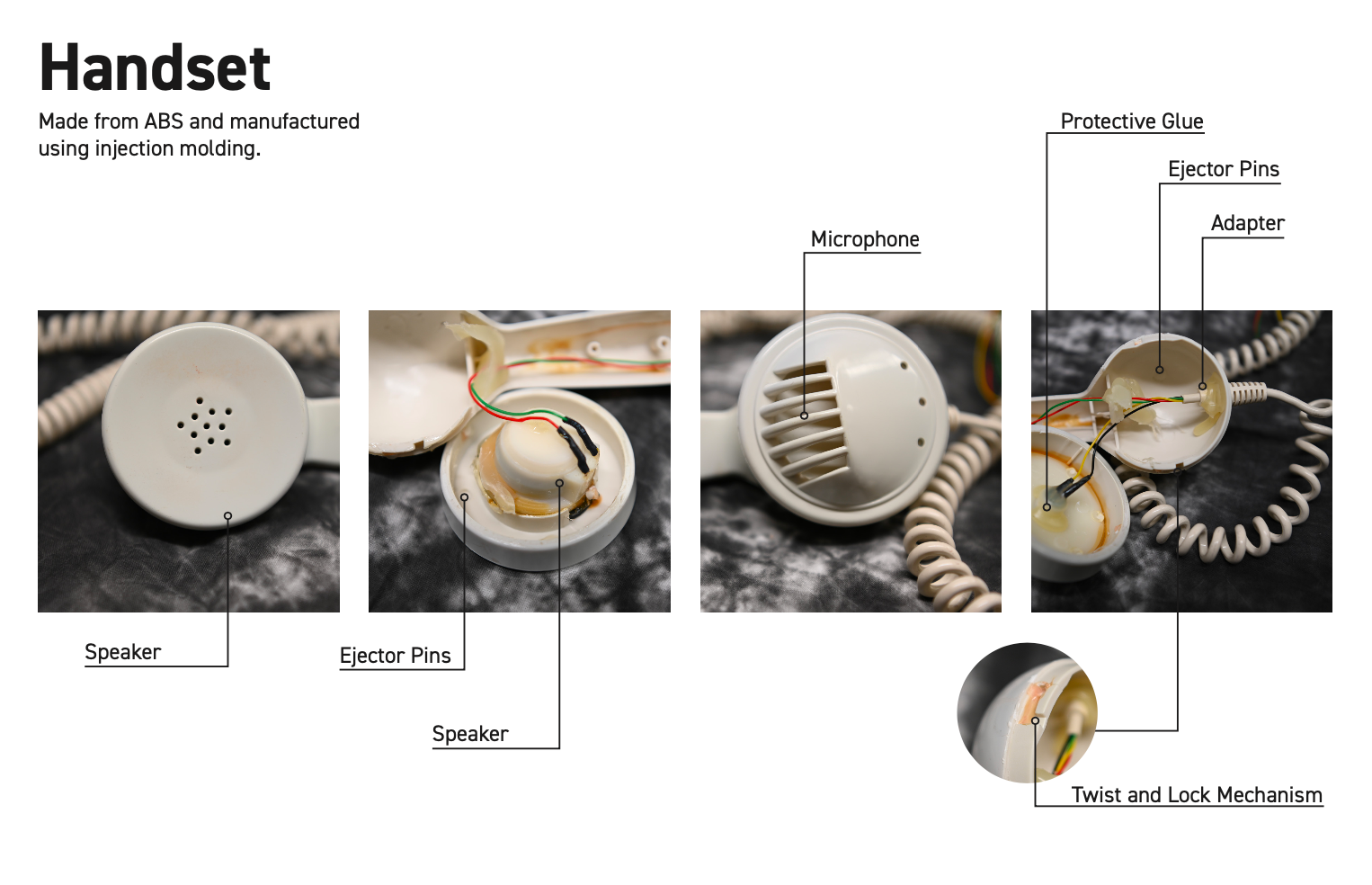

HANDSET

The handset is also made from ABS plastic while the cord of the handset has polypropylene insulation and a polyvinyl chloride cover.

Interestingly, the phone has a weight in the handle of the handset to give the phone a hefty feeling.

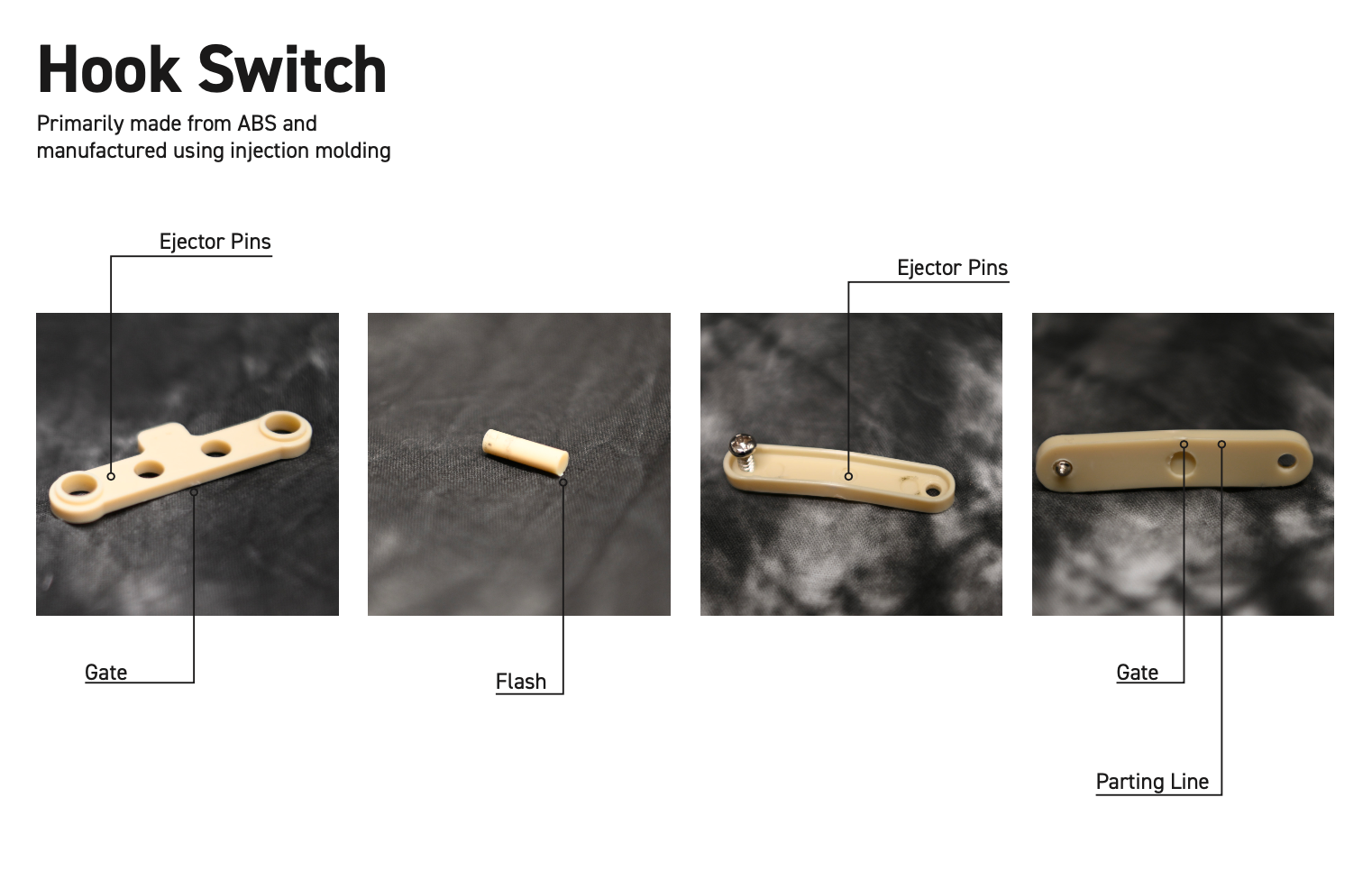

HOOK SWITCH

The plastic portions of the hook switch are made using ABS and manufacturing using injection molding. It is easy to see the ejector pin and gate marks on these smaller pieces.

The handset hanger is likely made from some type of cast steel.

Hook Switch

Hook Switch

Hook Switch

This project created the foundation for the Grand Kitchen Timer. Make sure to check it out!